Published on

February 23, 2015

Category

Features

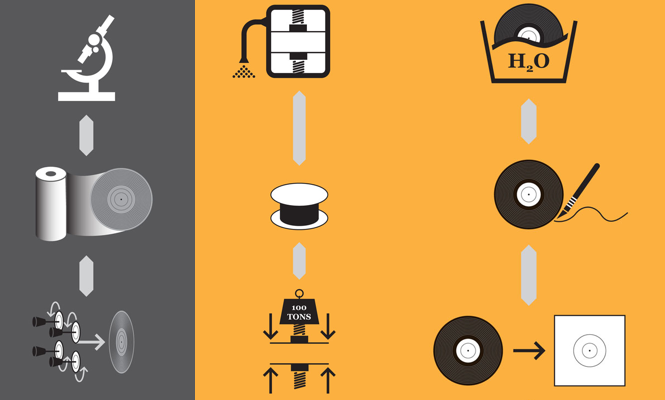

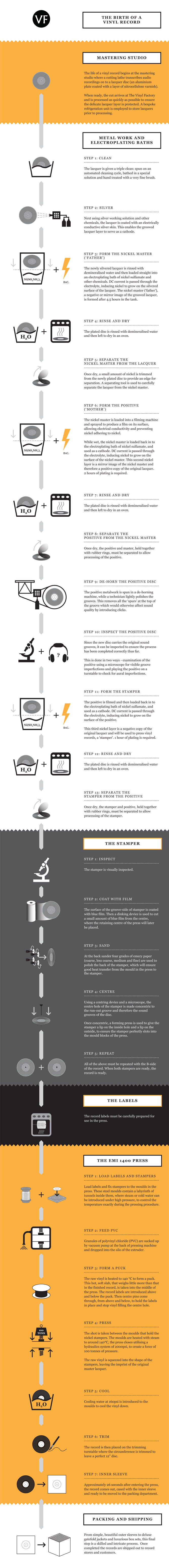

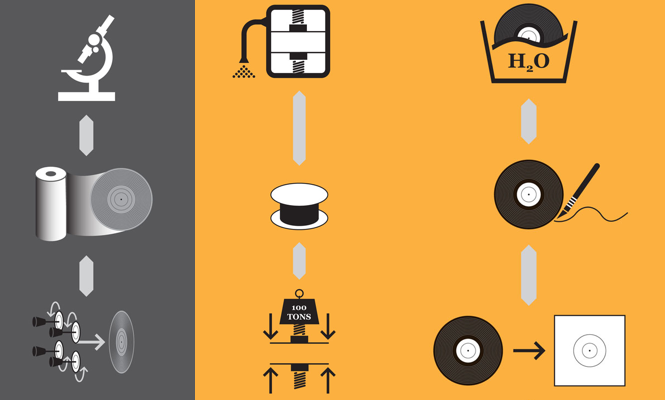

Our step-by-step infographic reveals the exact magic that goes into creating a record.

You’ve had a peek inside our pressing plant, zooming in and out at the machinery behind the music. Now fill in the gaps with our illustrated infographic which delineates every step of the production system.

From lacquer creation in the mastering studio to metalwork operations and the pressing procedure, there are many intricate and highly labour intensive processes needed to keep the vinyl spinning on your turntable. Check out how we do it below:

Illustration: Jonathan Chadwick